School & Personal Projects

On this page are my favorite school and personal projects. I am particularly enthusiastic about projects involving robotics and prototyping.

Atlas Jamming on the Drums

The idea of this project is to have the humanoid Atlas robot play on a drum set in Rviz. The focus of this project was rooted in trajectory generation for manipulators. In this case, the manipulators are Atlas’ arms. An algorithm was developed that takes a desired sequence of drum “hits” and generates trajectories such that Atlas hits each drum member at the correct time. Additionally, a secondary task was chosen to make Atlas dance. This project utilized several topics from Caltech’s ME 133A: Robotics course. Atlas jams to “Outstanding” by The Gap Band.

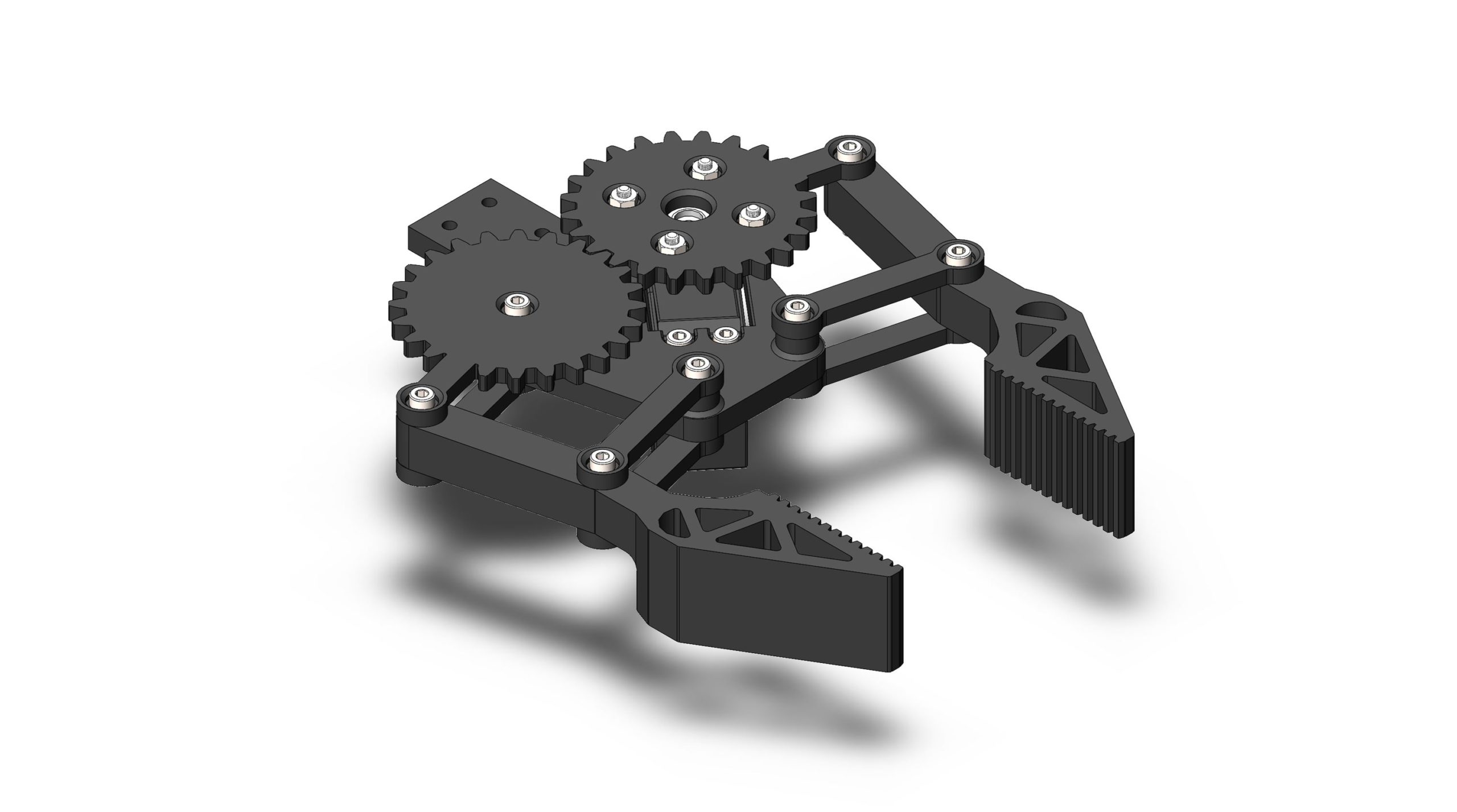

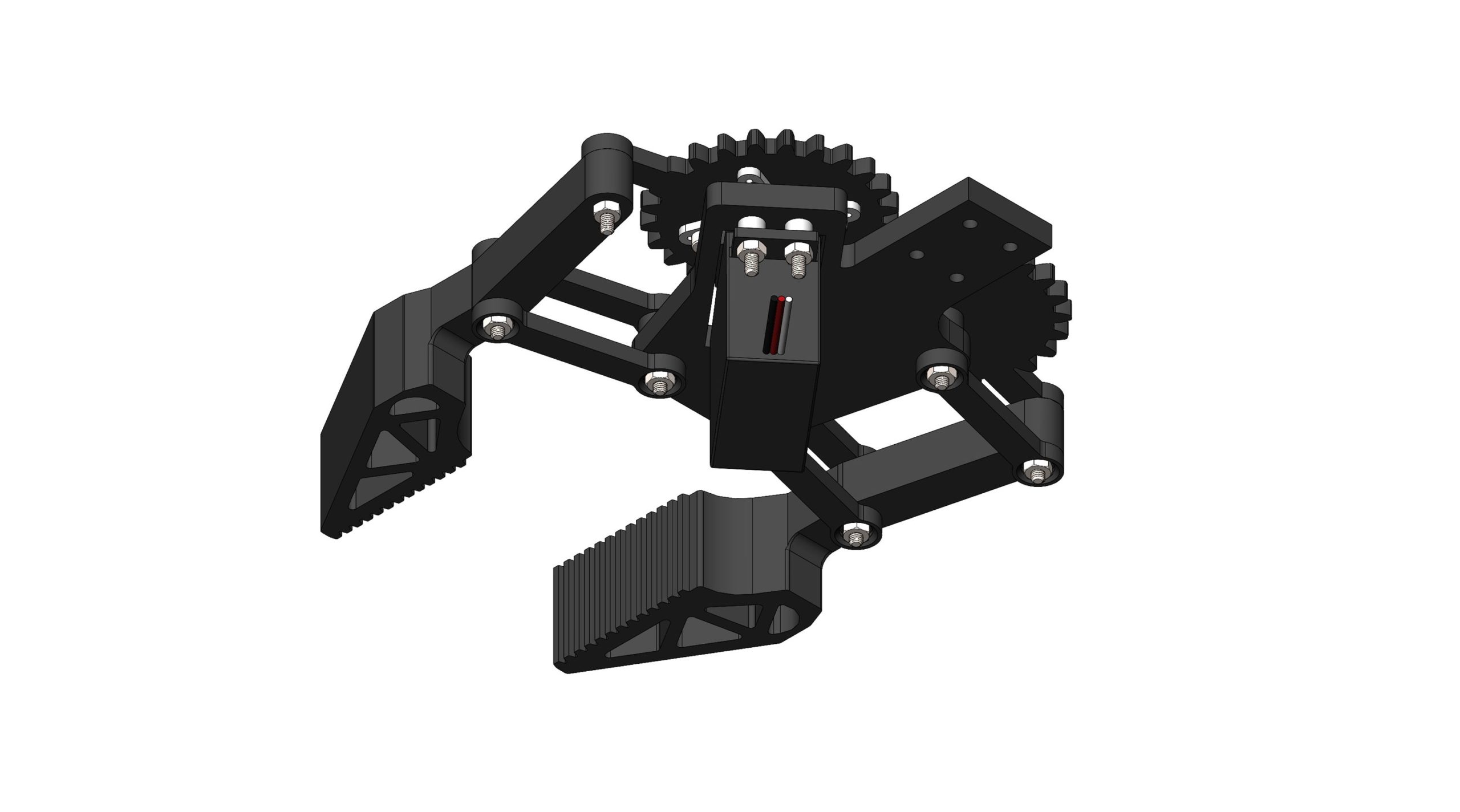

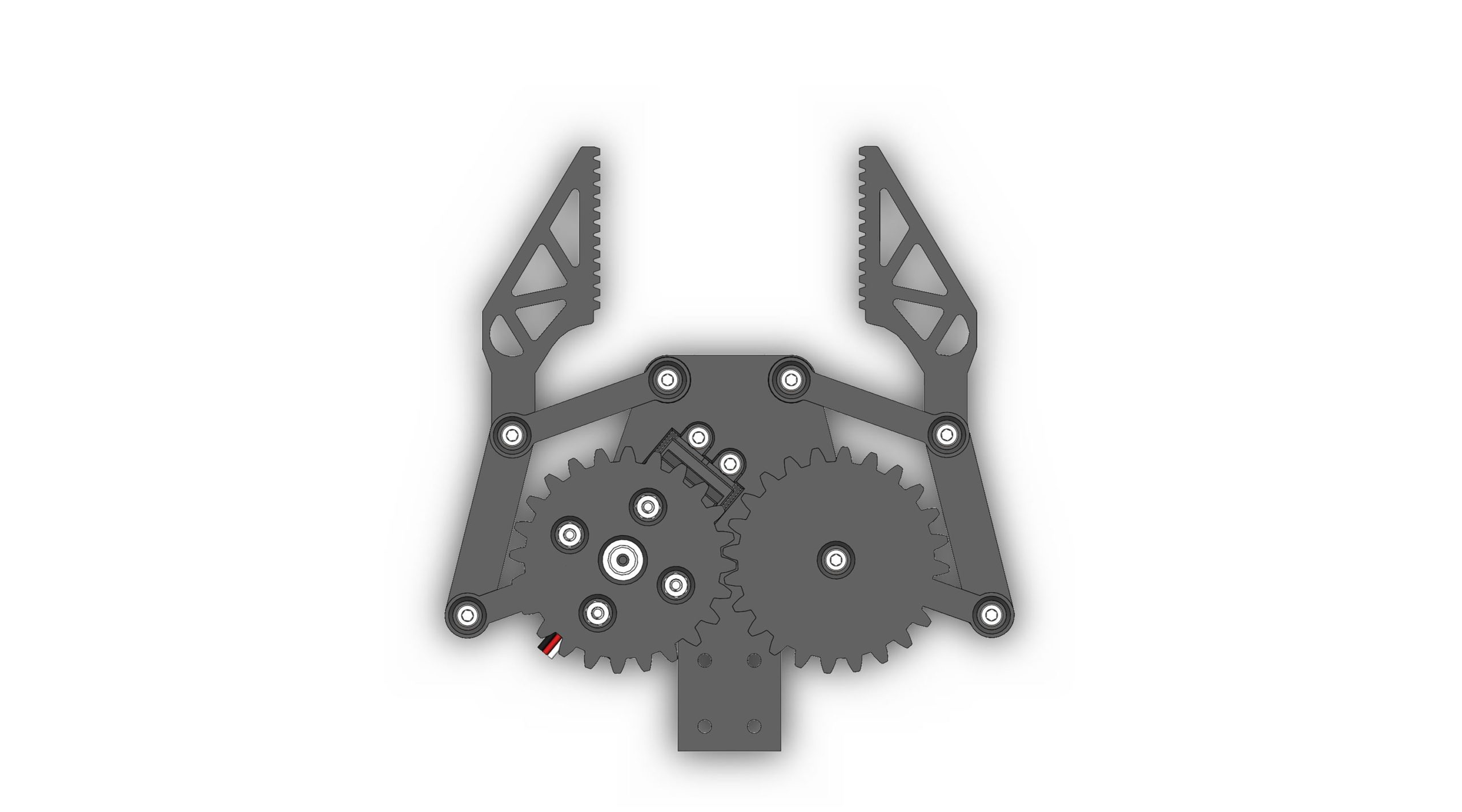

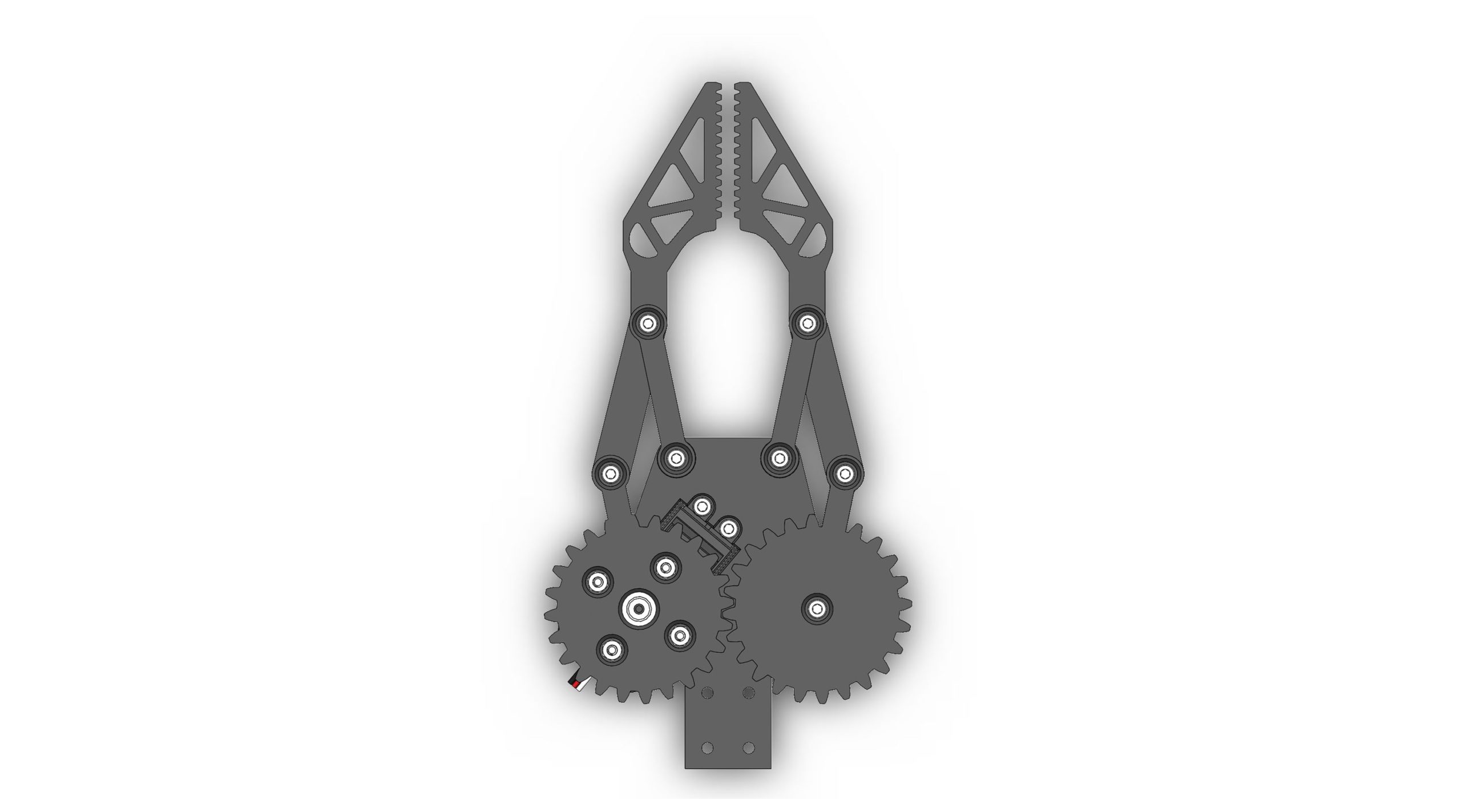

Mechanical Design for an End Effector

End Effector

End Effector End Effector

End Effector Open

Open Closed

Closed

This is my design for an end effector. I plan to design and build a robot manipulator but wanted to start with one of the more interesting parts. This end effector is actuated with a single Futaba servo. This end-effector was 3D printed to verify its efficacy. The gripper can open as large as 2.7 inches and can completely close.

Pi Bot (ON Steroids)

Pi Bot

Pi Bot Pi Bot

Pi Bot Pi Bot

Pi Bot Video Streaming and Control

Video Streaming and Control

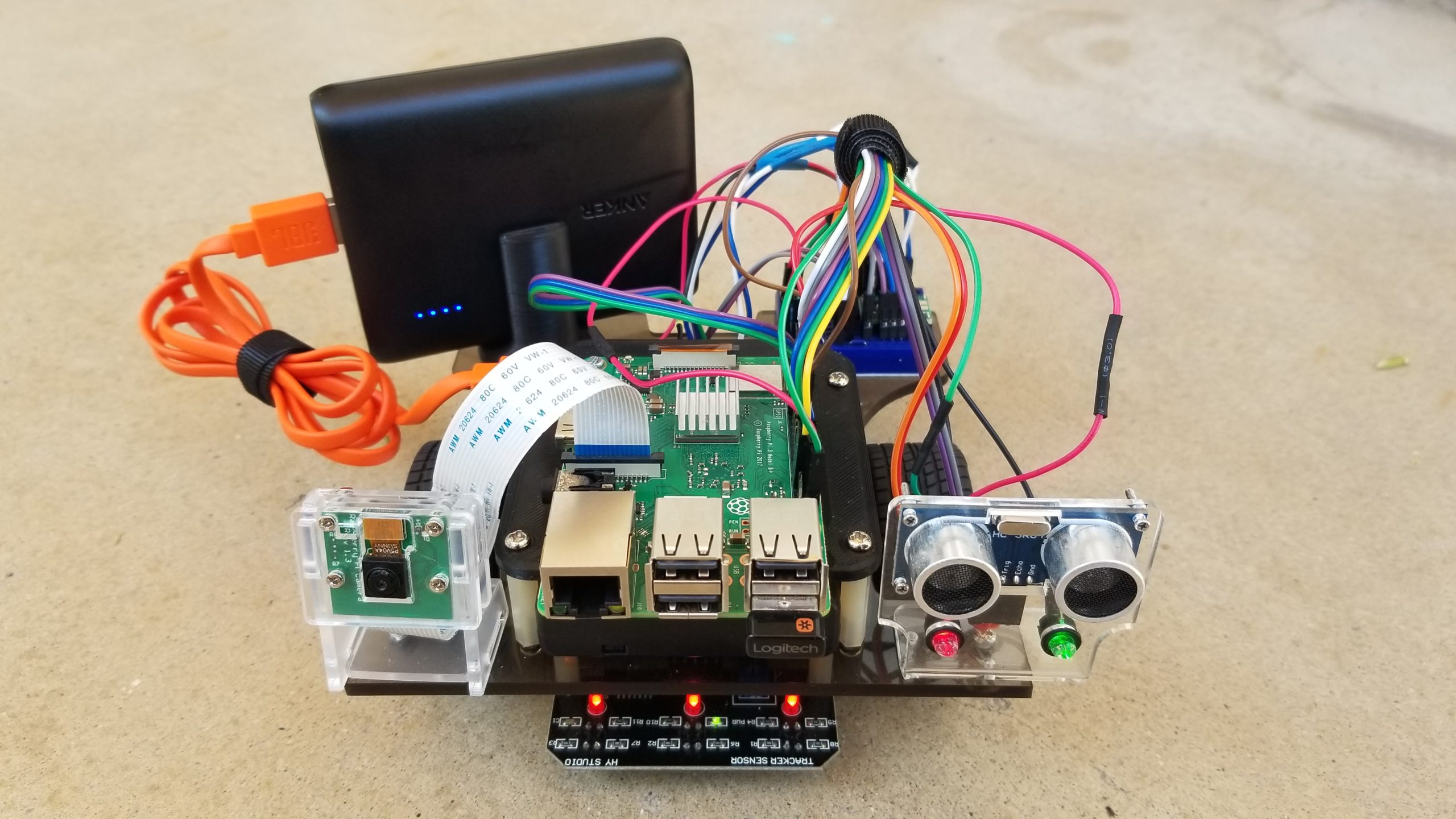

The purpose of this project is to demonstrate my programming, mechanical design, electronics, and robotics skills. I added a camera for real-time streaming via a WiFi network, replaced the Arduino controller with a Raspberry Pi 3B+ (running Ubuntu MATE), designed and 3D printed custom parts, made custom jumper wires, and upgraded the battery packs for the motors and Raspberry Pi. I used the Robot Operating System (ROS) to orchestrate the robot’s mobility, real-time camera streaming, and ultrasonic sensing. To drive and steer the Pi Bot, I used an Xbox ONE controller. I wrote custom Python scripts and used them as ROS nodes. My code is maintained on GitHub.

Low-cost System Dynamics and Controls Platforms

Pendulum Platform

Pendulum Platform Pendulum Platform

Pendulum Platform Pendulum Platform

Pendulum Platform Pendulum Step Input - Simulink

Pendulum Step Input - Simulink Pendulum Step Input - LabView

Pendulum Step Input - LabView Pendulum PID Control - Simulink

Pendulum PID Control - Simulink Pendulum PID Control - LabView

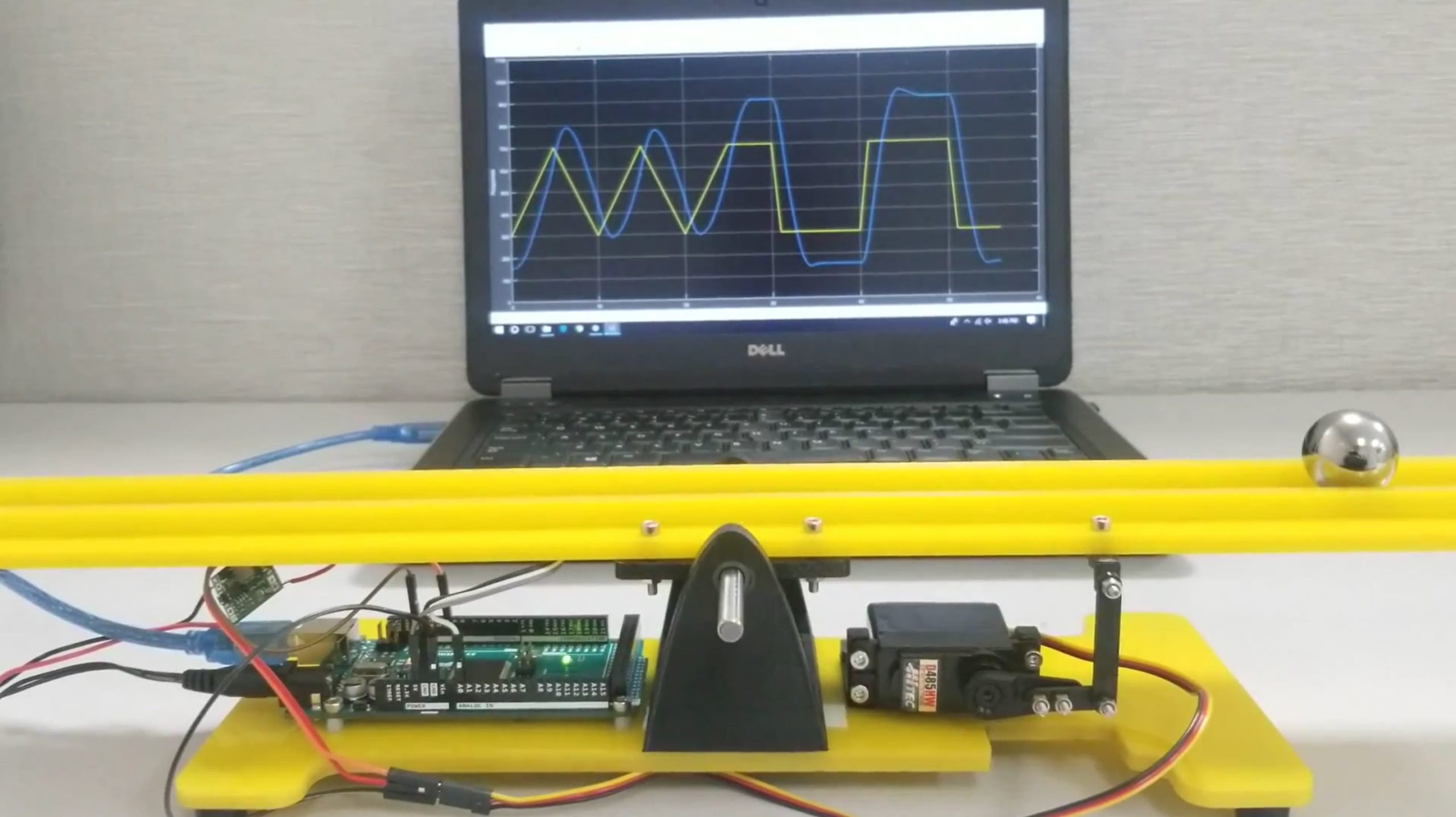

Pendulum PID Control - LabView Ball and Beam Platform

Ball and Beam Platform Ball and Beam Platform

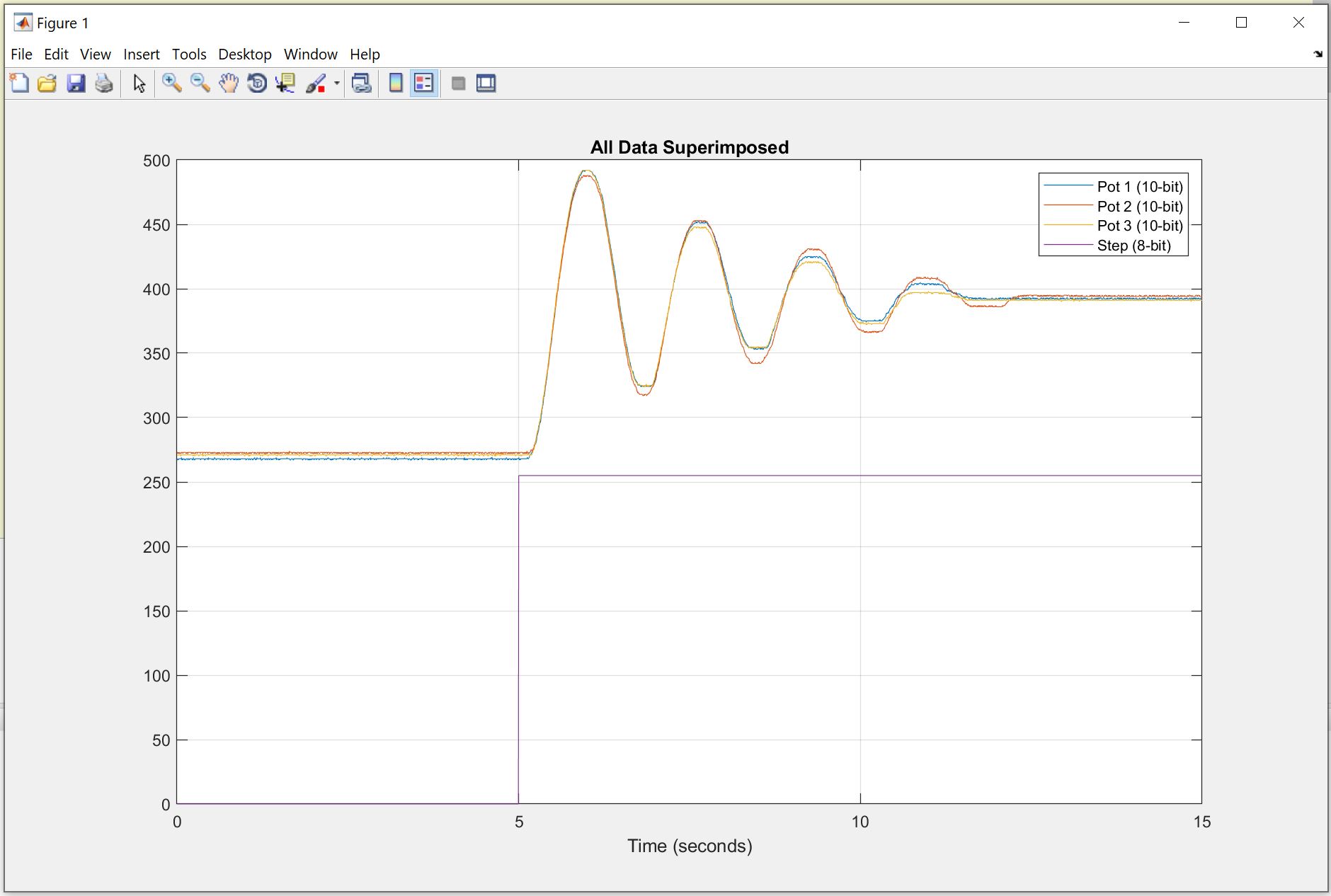

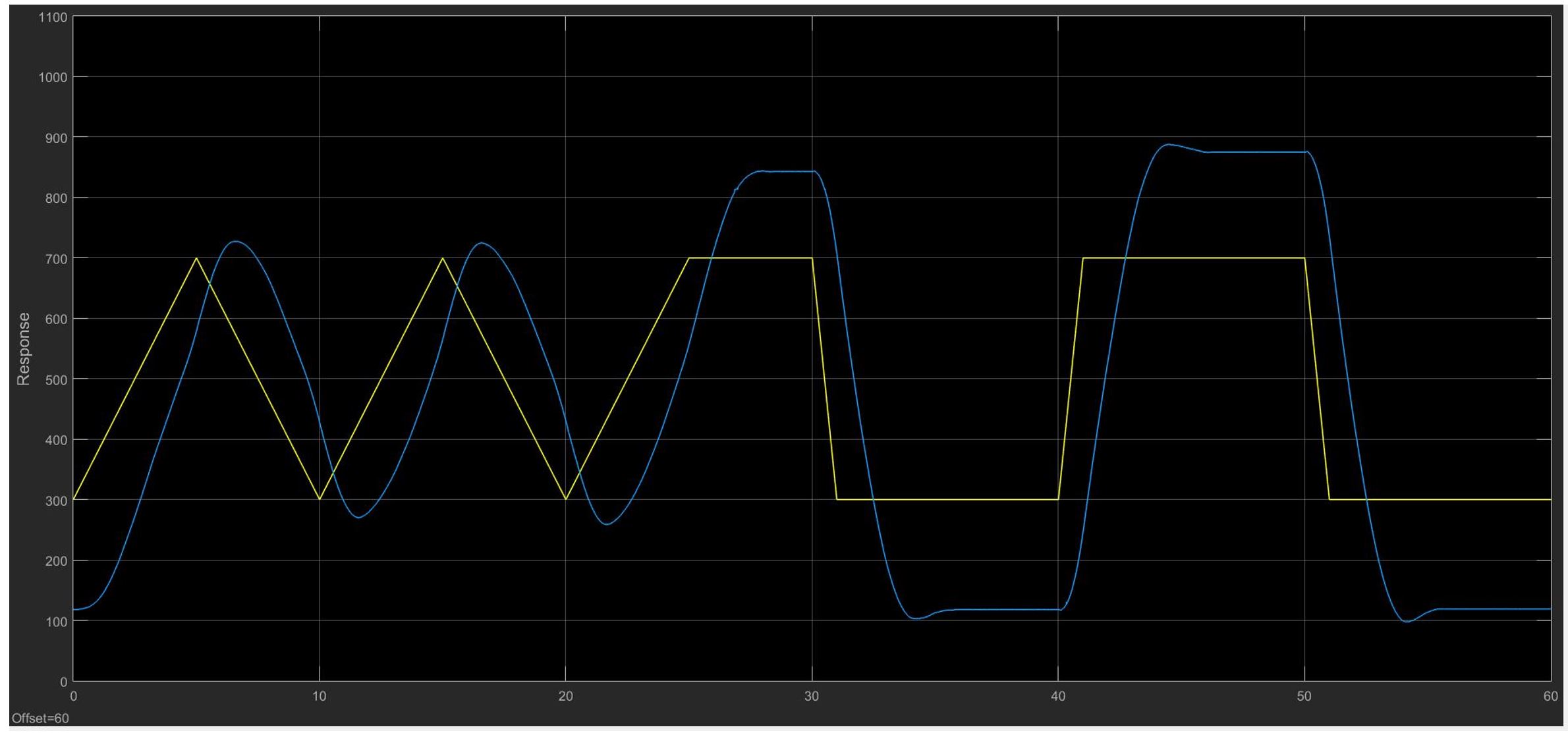

Ball and Beam Platform Ball and Beam PID Control - Simulink

Ball and Beam PID Control - Simulink

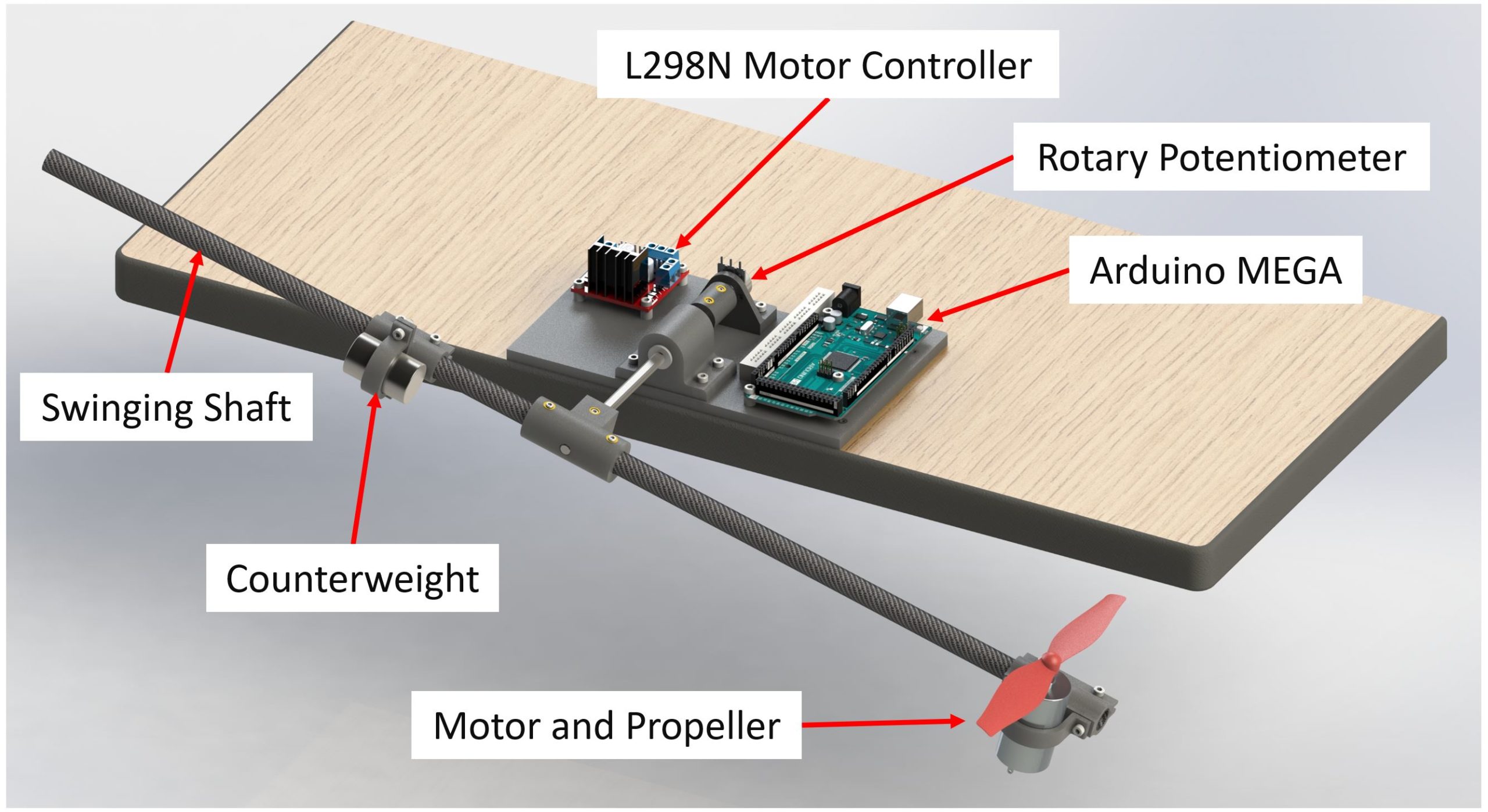

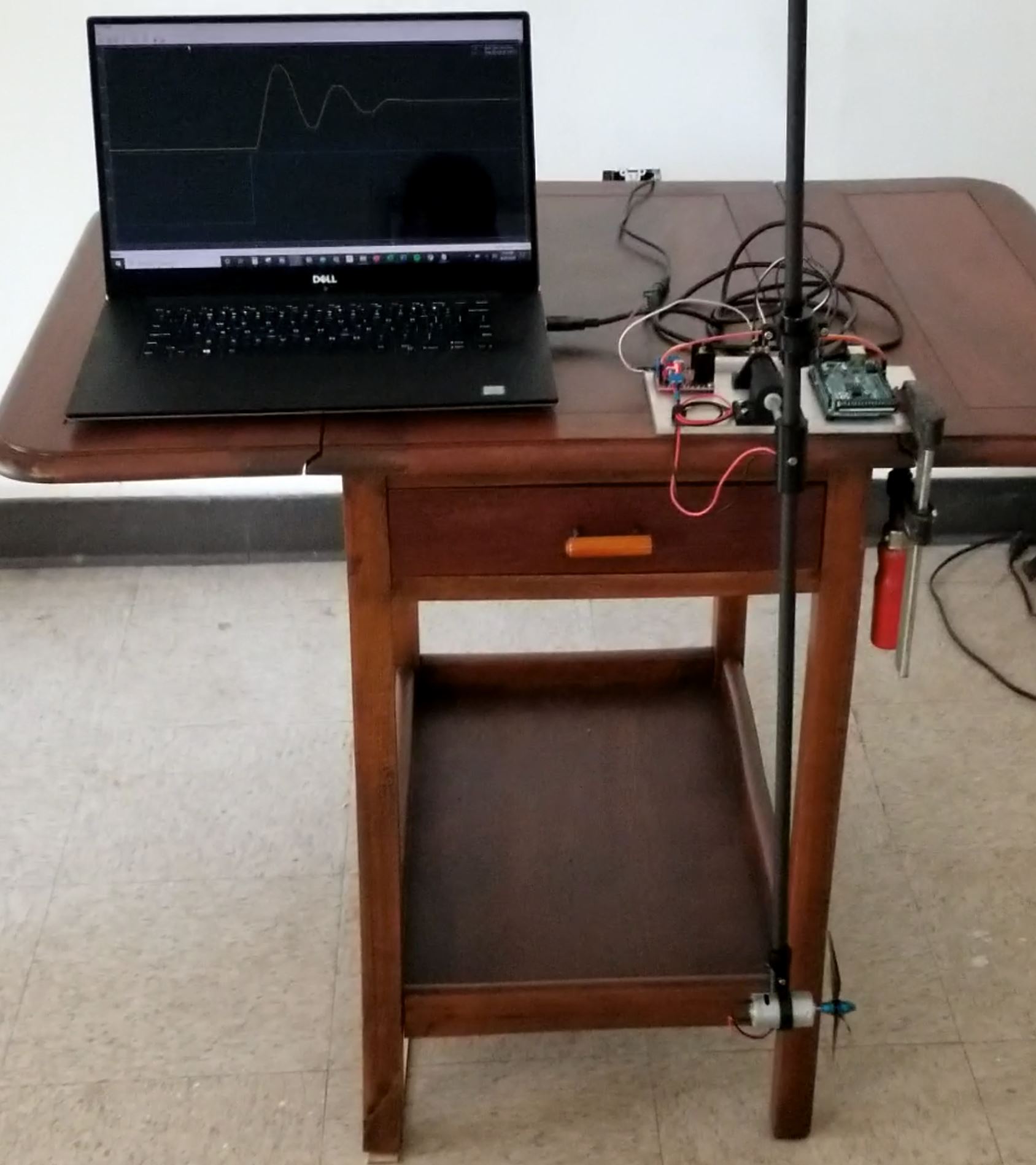

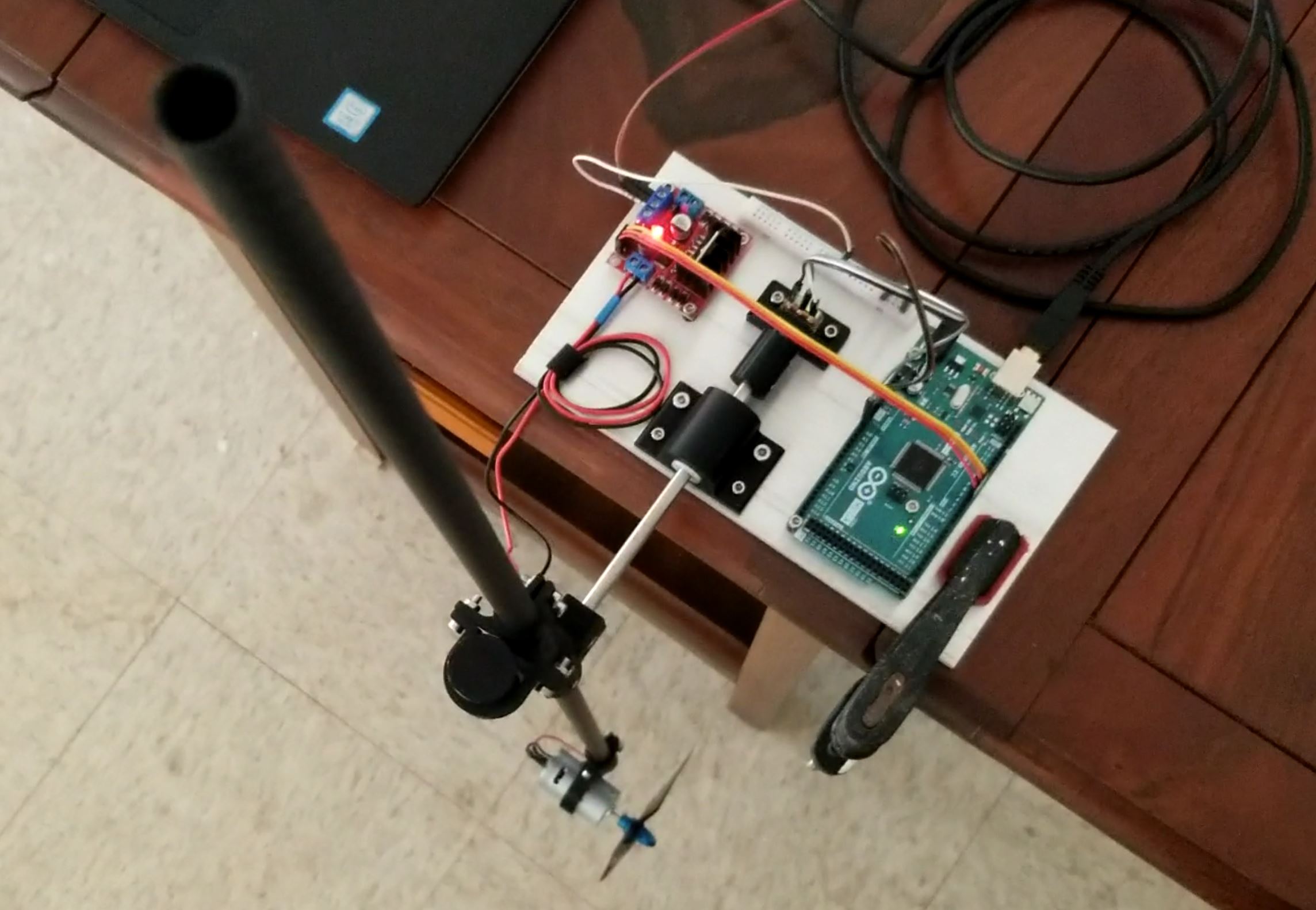

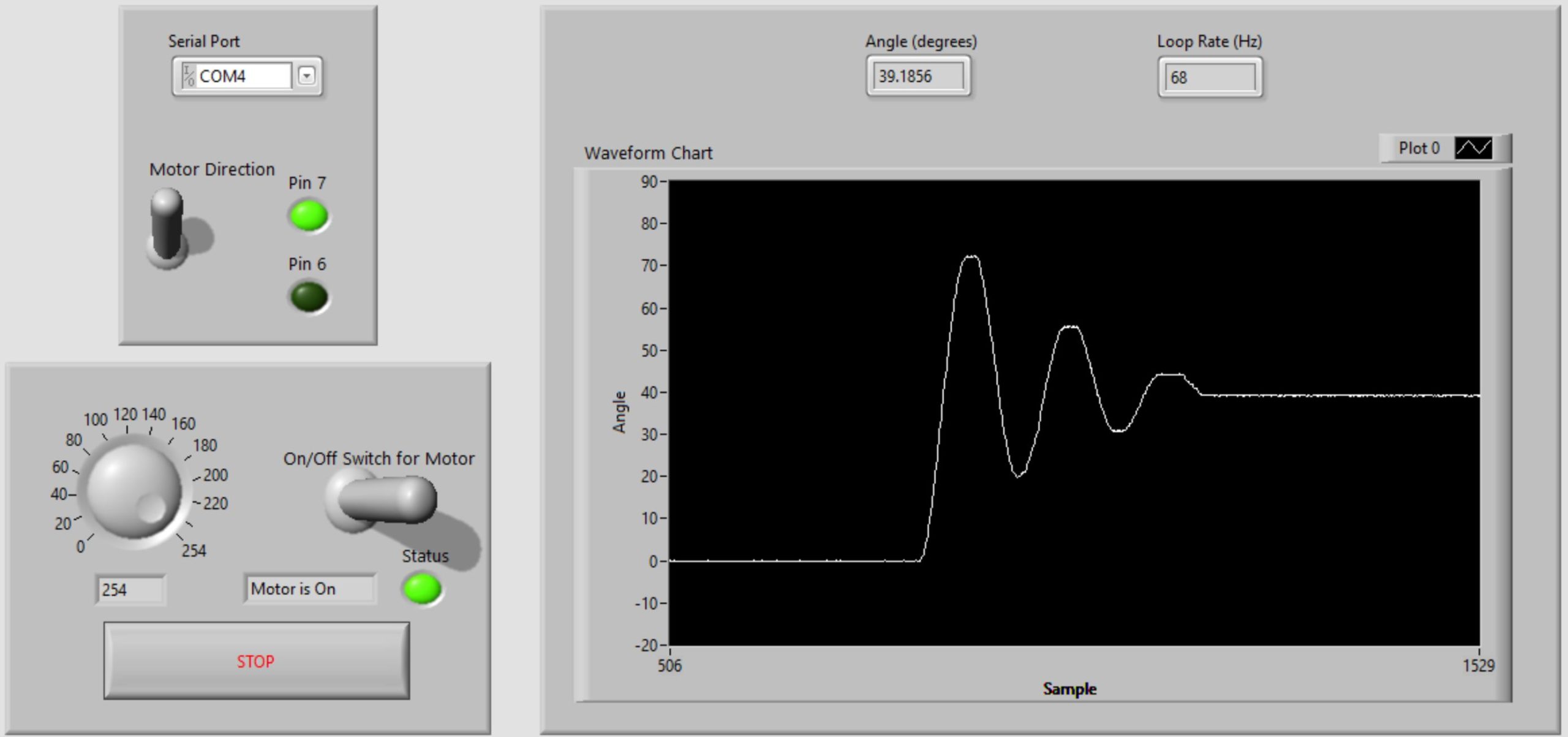

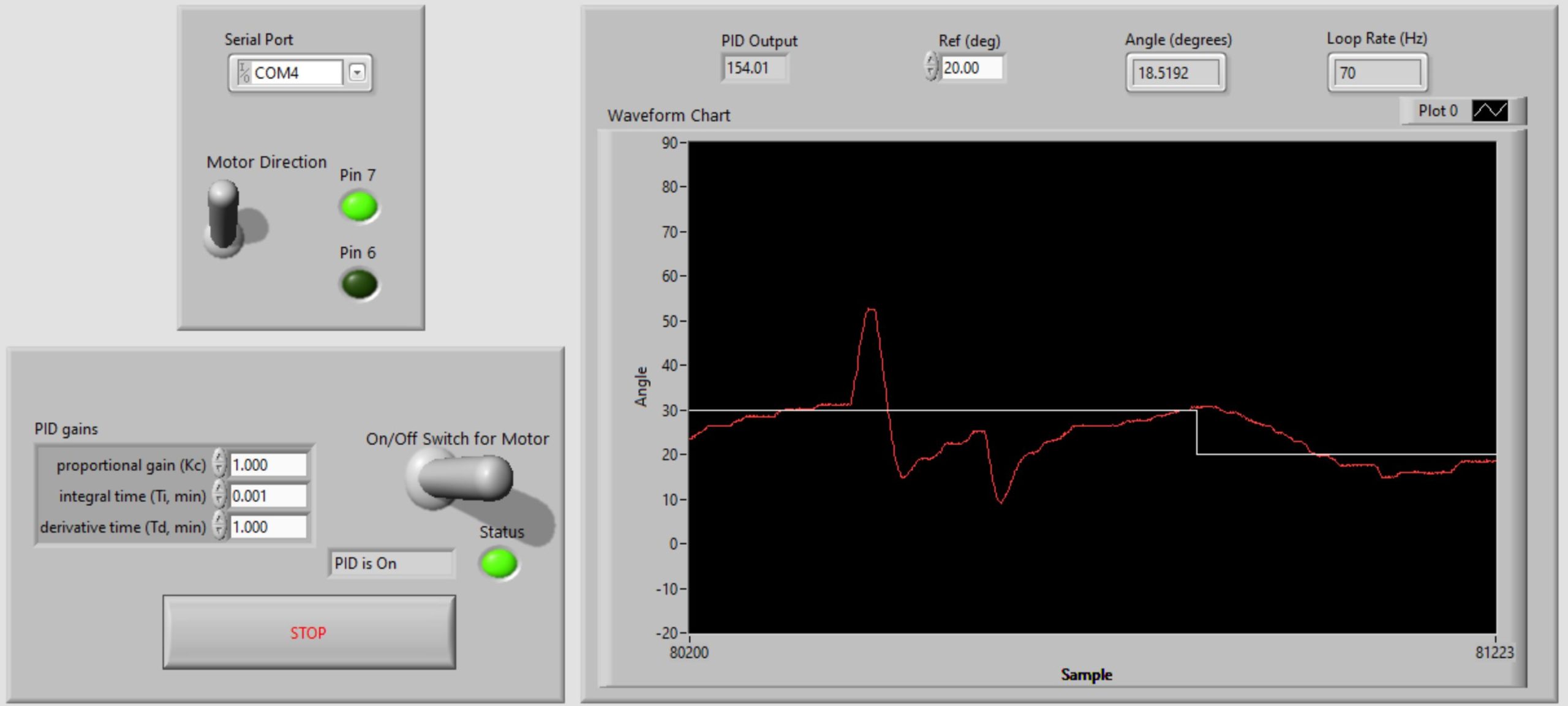

- Pendulum Platform: I designed this apparatus for educational system dynamics experimentation. The plant was purposefully made with a sub one-hundred-dollar budget in order to increase affordability for undergraduate students. This platform was designed to optimize cost, simplicity, and mobility. It can be used for system identification or controls exercises. The plant consists of few electronic elements, 3D printed parts, carbon fiber tubes, and a motor and propeller assembly. The platform can easily be assembled/disassembled and clamped to any table. The plant can be programmed using MATLAB/Simulink, LabView, or Arduino. Included in the photos are screenshots of some data when the plant is subjected to a step input and a PID controller.

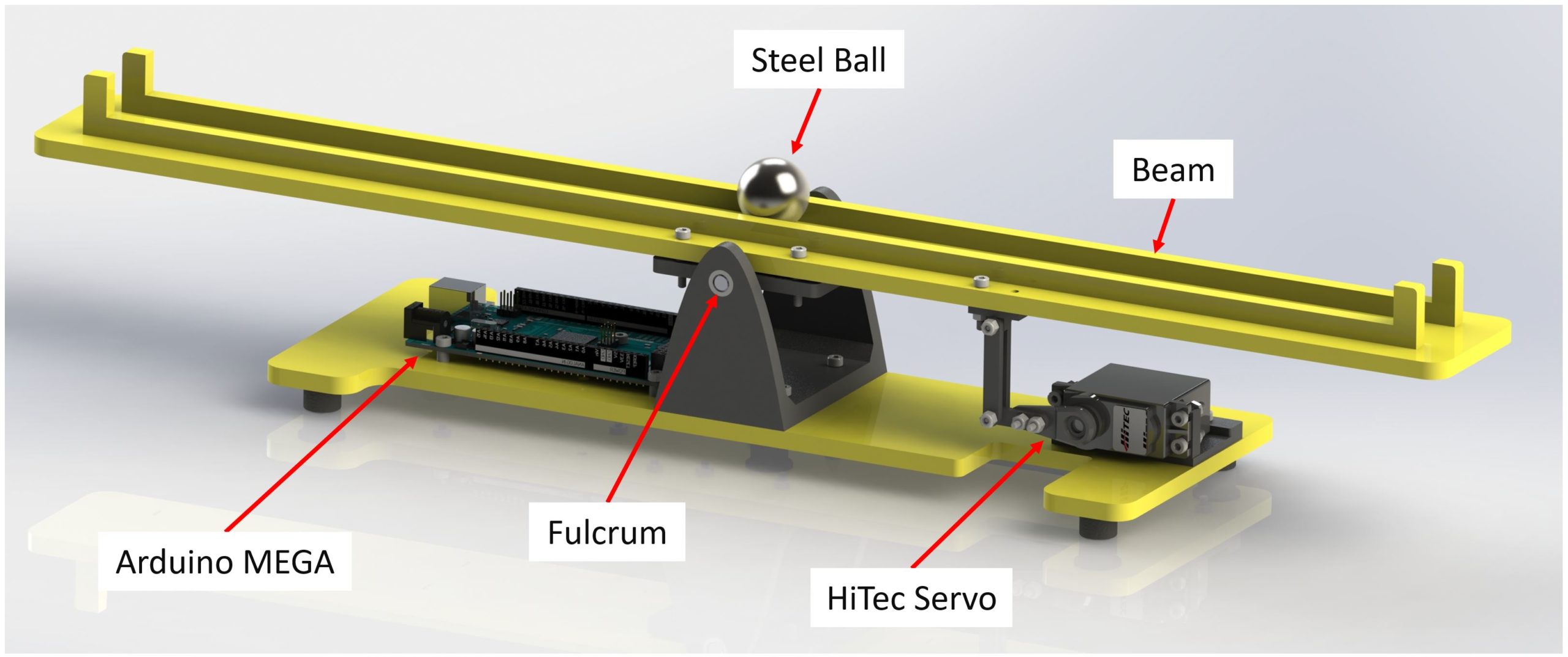

- Ball and Beam Platform: Like the Pendulum platform, I designed this apparatus for educational purposes and to optimize cost, simplicity, and mobility. This plant is used for controls experimentation. The plant can also be programmed using MATLAB/Simulink, LabView, or Arduino. The metal ball rolls to different points of the beam while the servo controls the slope of the beam to keep the ball at a specific location on the beam.

- A paper was submitted and accepted to the American Society for Engineering Education (ASEE) – 2021 Annual Conference & Exposition. The paper concerns the pedagogical function of these plants. See the abstract for more information.

Flyball Tachometer

Fly-ball Tachometer

Fly-ball Tachometer Fly-ball Tachometer

Fly-ball Tachometer

The purpose of this fly-ball tachometer is to demonstrate the measurement of rotational velocity via an ultrasonic sensor and rising platform. The electronics consisted of an AC to DC converter, a DC motor with a hall effect sensor encoder, a motor controller, an LCD screen (to display RPM), a potentiometer (for motor speed adjustment), an Arduino UNO R3, and an ultrasonic sensor. A curve fit was created by taking several data points of the height of the platform versus encoder RPM. The curve fit was then used to determine the RPM of the shaft using the ultrasonic sensor height data.

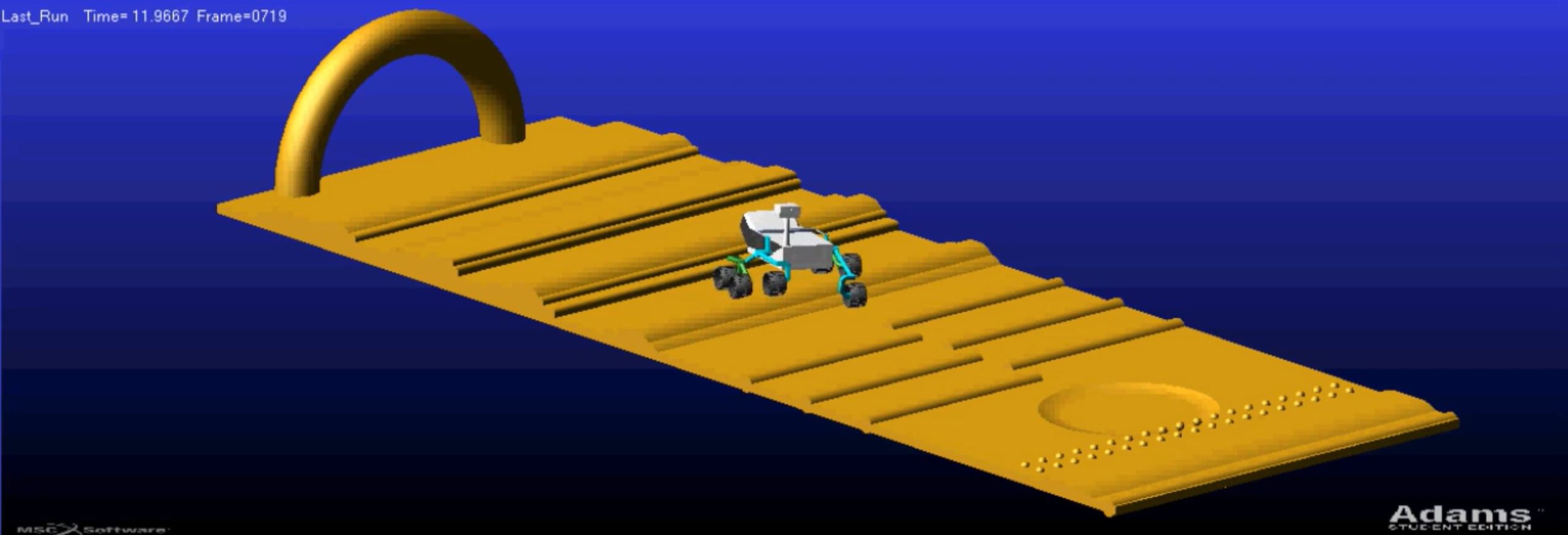

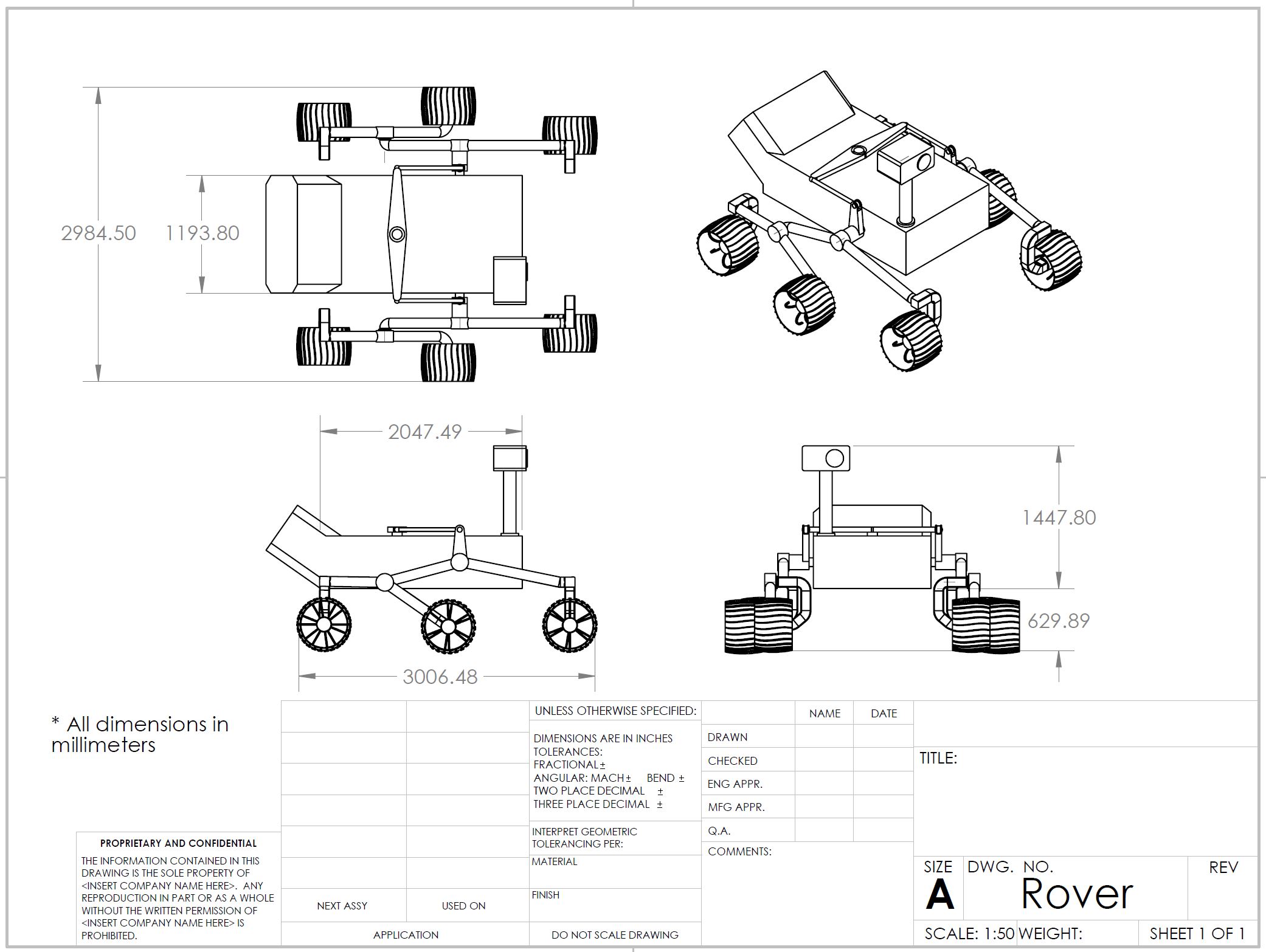

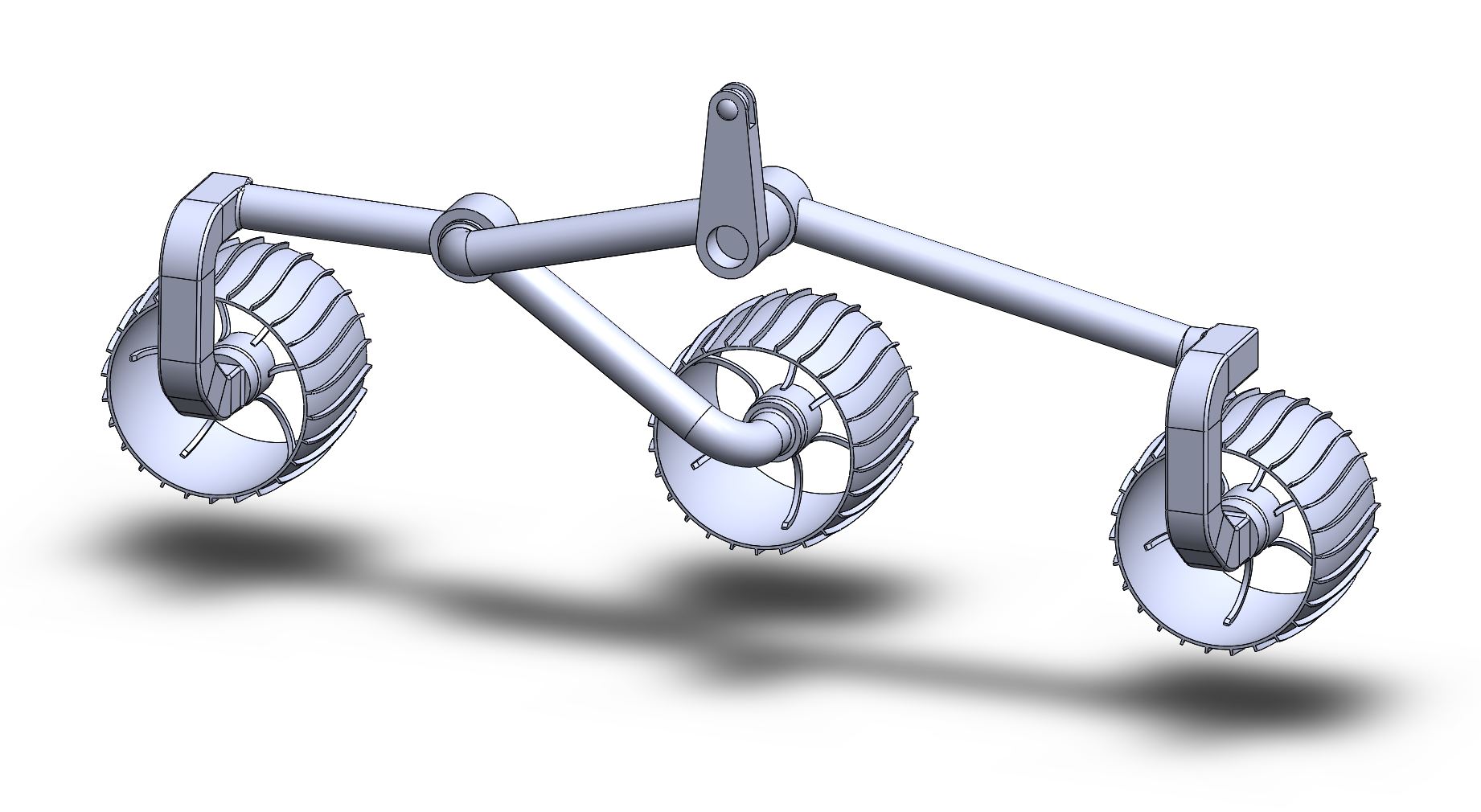

Mars Rover Rocker-Bogie Suspension Design and Simulation

MSC ADAMS Simulation

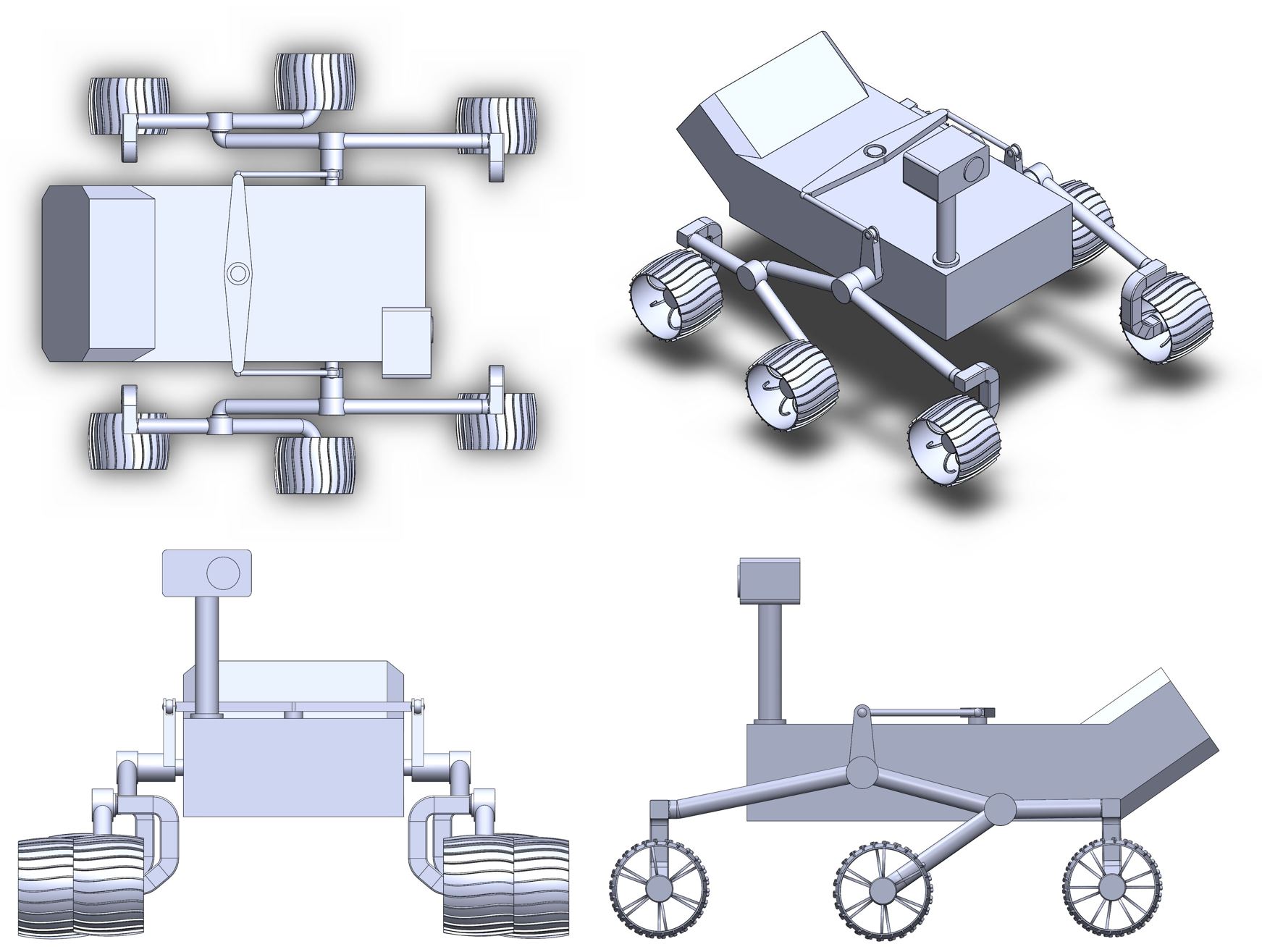

MSC ADAMS Simulation Mars Rover Solidworks Design

Mars Rover Solidworks Design Mars Rover Solidworks Design

Mars Rover Solidworks Design Design of the Rocker-Bogie

Design of the Rocker-Bogie

I designed a lightweight version of the Mars Perseverance/Curiosity Rover on SOLIDWORKS and used it for ADAMS simulations. The rover model was tested on bumpy terrain with Mars gravity. The passive dynamics of the rocker-bogie was observed when actuation only occurred at the wheels.

Click to see the ADAMS simulation

UR3 Manipulator Robot

For a graduate-level robotics course at my undergraduate institution (ME 5711 – Fundamentals of Robotics), the UR3 manipulator robot was used to test theoretical knowledge. Some experimental topics included inverse and forward kinematics, robotic end-effectors, work spaces, revolute joints, static force analysis, and programming.

PVC Pipe Cutter

PVC Pipe Cutter

PVC Pipe Cutter PVC Pipe Cutter

PVC Pipe Cutter

This machine was designed to facilitate the process of cutting various diameters of PVC pipe. The pipe sits on the ”V” contour of the machine and then is cut using a second-class lever and blade. The blade of a Bowie knife was repurposed to cut PVC piping. I machined all components at my undergraduate institution’s machine shop.

Fabrication of Metal Truck

Metal Truck

Metal Truck Casting

Casting Welding

Welding

This truck was fabricated for a manufacturing engineering lab. Several methods of manufacturing were incorporated. The truck chassis was made using a green sand casting and then cleaned up with grinders and a vertical mill. The truck bed was a product of sheet metal working, spot welding, and shearing. The four wheels were made on a CNC lathe and the fifth (not observable in the picture) was made on a manual lathe. Fastening operations were also performed. I poured molten metal for a lost foam casting process (I’m on the left in the photo). I TIG and MIG welded the truck’s pedestal using thick pieces of sheet metal.

Caltech Rapid Prototyping Trophy

This trophy was fabricated for Caltech’s ME 13 Introduction to Mechanical Prototyping course. I manufactured this trophy during my Caltech research internship. The aluminum platform was machined using a vertical mill, the acrylic label was made using a laser cutter, the brass shaft was machined using a manual lathe, the gear platform was sandblasted and cut on a water jet cutter, and the ”MCE” logo was 3D printed.